Introduction

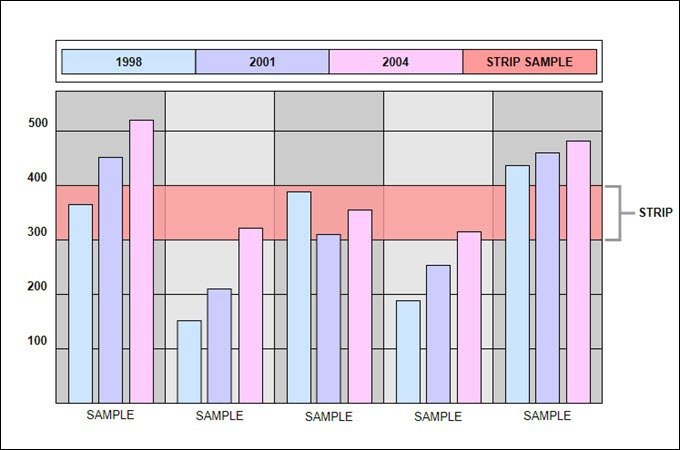

When it comes to visualising data in a simple and reliable way, strip charts are the winner. But what are strip charts? Imagine a roll of paper scrolling beneath a pen or digital equivalent that draws out data over time—a simple but powerful tool. Strip charts capture fluctuations, trends and data behaviour that help industries keep their finger on the pulse of complex processes. From a pharma line to sound levels in a city centre, strip charts are everywhere, often invisible but vital.

Temperature Recording

Process Control and Monitoring

Ever baked a cake without checking the temperature? A small mistake can mean the difference between a lovely loaf and a brick. Now imagine that level of precision scaled up to making medicine or chemicals. Strip charts are used to monitor temperature in these environments, so processes run smoothly and safely. In industries where the margin for error is tiny, keeping to optimal operating conditions isn’t just recommended—it’s essential.

For HVAC systems strip charts are useful for tracking temperature over time so technicians can diagnose faults before they become big problems.

Methods of Temperature Measurement

When it comes to recording temperature there are a couple of main options:

- Thermocouple Method: Thermocouples are a popular choice. Why? They’re simple and can measure a wide range of temperatures. Connected to a strip chart recorder a thermocouple’s data becomes a visual line that tells a story of heat and change.

- Resistance Method: Resistance temperature detectors (RTDs) provide accurate temperature readings by measuring electrical resistance which changes with temperature. Strip charts connected to RTDs create a detailed history, a goldmine for engineers in industries like pharma where precision is non-negotiable.

Case Studies

Take the food industry. A strip chart attached to a thermocouple during a pasteurisation process ensures temperatures hit the sweet spot for safety and quality. In chemical manufacturing strip charts record reactions in real-time so dangerous temperature spikes that could be catastrophic don’t happen. It’s not an exaggeration to say strip charts can be the difference between safety and chaos.

Sound Level Monitoring

Environmental Monitoring

Noise might be an everyday annoyance for some but in regulated environments it’s a big problem. Whether it’s the roar of jet engines near an airport or the hum of traffic in a city centre, sound levels need to be monitored. This is where strip charts come in, capturing sound level data and making it visible.

Equipment Used

Microphones and sound level meters connected to strip chart recorders are the tools for the job. The strip chart doesn’t just take a snapshot; it creates a long, continuous record of sound data over time. It’s like having a memory you can unroll and look at whenever you want.

Benefits of Sound Level Recording

Why does this matter? Long-term data collection is essential for complying with regulations and urban planning. Town councils, airports, and highway authorities use strip charts to plan noise mitigation strategies, ensuring residents can sleep peacefully. This is not just about following rules; it’s about quality of life.

Recording Amplifier Drift

Understanding Amplifier Drift

Ask any sound engineer or telecommunications expert, and they’ll tell you that amplifier drift can make or break a project. Amplifier drift occurs when the temperature causes slight shifts in transistor bias, altering the operating points. It’s a subtle gremlin, but strip charts help engineers catch it in the act.

Monitoring Techniques

Strip charts connected to amplifier outputs record these tiny deviations in real-time. That continuous trace isn’t just a squiggle; it’s a warning sign, a pattern, and a lifeline for maintaining quality control.

Applications in Electronics and Telecommunications

In audio systems and comms networks signal integrity is key. Strip charts help technicians keep signals clean and prevent distortions that can lead to garbled comms. It’s like listening for static on a call but on a more scientific and long term basis.

Real Time Data Visualization in Automation

Use in Programmable Logic Controllers (PLCs)

In automation real time data isn’t a nice to have it’s a must have. Strip charts are often used with programmable logic controllers (PLCs) to visualise data as it happens. The combination allows engineers to see a machine’s heartbeat as a simple line graph. This isn’t just a graph it’s a lifeline that keeps systems running.

Troubleshooting and Tuning Processes

Engineers love their gadgets but nothing beats a tool that makes troubleshooting easier. Strip charts do just that by giving a clear view of real time data. They can help you see when a system started to go wrong and why. When it comes to fine tuning operations a strip chart is like a trusted co-pilot that shows you what went wrong and where to improve.

Examples of Industries Using This Technology

From assembly lines in car manufacturing plants to energy grid controls, industries rely on real time data visualisation. In energy for example monitoring power loads helps prevent blackouts, in transportation data from strip charts helps with logistics.

Telecommunications

Real Time Signaling Analysis

In telecommunications strip charts are used in signaling analysis. Real time capture of pulse-code modulation (PCM) data is critical for clear comms. Strip charts give a continuous unbroken view of the data flow so engineers can catch the inconsistencies and ensure service is reliable.

Monitoring Voice Transitions and Signaling Relationships

Voice quality matters especially in sectors like call centres or emergency services. Monitoring with strip charts makes it easier to ensure signals are consistent. When engineers can see voice transitions over time they can make the tweaks to keep service running.

Case Studies from Telecom Companies

Several telecoms use strip charts to monitor and troubleshoot voice and data quality. By tracking minute changes these charts help with preventative maintenance and reduce outages and customer dissatisfaction.

Other Industrial Applications

Medical Monitoring

In medicals strip charts have a big role. Used in ECGs, EEGs and other physiological tests they provide a continuous printout of patient data. Imagine being in an ER and needing to see how a patient’s heart rate changed throughout the day. A strip chart is there waiting to roll out its record.

Environmental Monitoring

Whether it’s air quality measurements or water levels strip charts make complex data easy to see. Scientists and environmentalists use them to track changes over days or months and create a timeline for research and policy.

Research and Development

Strip charts are the unsung heroes of R&D labs. Whether it’s material testing, chemical experiments or physics labs these charts provide detailed records to be pored over. Their use in data collection helps teams spot trends that might otherwise be missed, saving hours of manual analysis.

Conclusion

Strip charts may not have the flashiness of digital dashboards or the allure of interactive graphs, but they hold their own when reliability is needed. Their ability to present real-time data simply and effectively makes them invaluable across industries, from manufacturing floors to hospitals. The humble strip chart continues to empower professionals, offering not just information but the clarity needed for critical decision-making.